Business presentations

SWIRE ENERGY SERVICES AS

Visit:

Bygg 87, NorSea Base

4056

Post:

P.O. Box 121

4098 Tananger

Norway

Tel: 51 65 38 00

swire@swirees.com

Web:

See PDF version

See listing here in

Offshore Norway

« Go back

The world's largest supplier of specialist offshore cargo carrying units

Operating since 1979, Swire Energy Services has become established as the world’s largest supplier of specialist offshore containers to the energy sector.

Today we provide a fully integrated service package that also encompasses aviation & refuelling, integrity, and chemicals services for customers across the oil & gas, offshore wind and marine sectors.

A new era of smart, connected services is required to meet the energy transition challenges of tomorrow. Today, we have grown from a world-leader in offshore containers, to become a fully integrated service provider for the global energy sector.

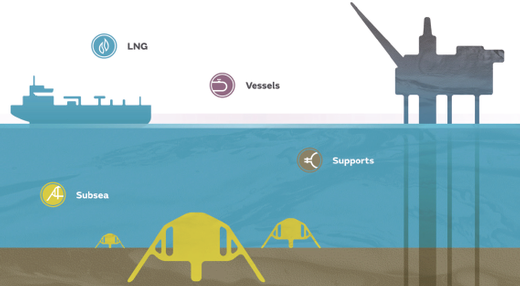

Offshore Container Services

Our rental service package is both comprehensive and unrivalled in the market today. Our services include:

• Full testing and inspection of units for the duration of the rental period

• 24/7 access to certificates

• Fully certified units to DNV 2.7-1, 2.7-2 and 2.7-3 when relevant

• Our multiple locations allow us to deliver from short distance

• Customer service support

• Fleet is designed to service the full spectrum of offshore oil & gas operations

• Most locations have in house repair & refurbishment facilities

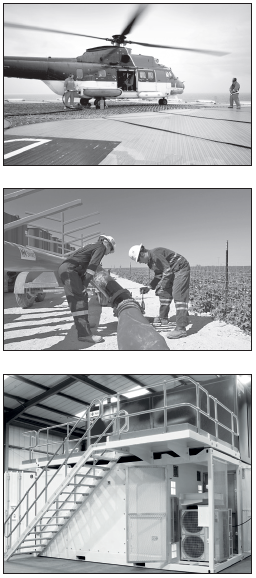

Aviation Services

Swire is leading supplier of offshore aviation services, and can offer a complete managed aviation service package, including equipment supply, training, audits, and fleet management. Our services include:

• Servicing, certification & repair of offshore helicopter refuelling systems in accordance with CAA’s CAP 437

• Helideck friction testing to CAS’s CAP 437

• Custom-designed and manufacture of Jet A1 fuel dispensing & pumping units to fit rigs and vessels to meet CAP 437

under CAA approval

• Certification, maintenance, and repair of customer-owned fuel transit tanks

• Repair and refurbishment of couplings and nozzles

• Training in every aspect of onshore and offshore helicopter refuelling

Integrity Services

Through out strategically located facilities, Swire can provide our clients with Asset Integrity services across Testing & Inspection, Engineering, Lifting, and Maintenance – in support of oil & as and offshore windfarm operations. Services include:

• Statutory Inspections Trained under GWO standards, our engineers are qualified to carry out statutory/LOLER inspections servicing Offshore Wind, Marine and Oil & Gas sectors

• Our LEEA qualified inspection engineers can undertake a wide range of LOLER inspections on fixed and loose lifting equipment

• Our integrated maintenance services – including refurbishment, painting, cleaning, and modifications – reduce delivery times and transport costs

• Lifting Equipment and solutions are available from all our 58 global base locations

• In-house surface preparation processes using our own blast and paint facilities

Chemical Services

Swire Energy Services provides specialist chemical management solutions for the handling, storage, transportation and delivery of high-value chemicals and essential oilfield fluids.

We offer only the highest quality tanks and equipment to provide secure, robust and reliable methods of chemical handling. Services include:

• Storage

• Handling of Products for Dispatch

• Blending

• Safety Advisor

• Chemical Sales

• Tank Rental & Management