BUSINESS PRESENTATION

TORGY MEK. INDUSTRI AS

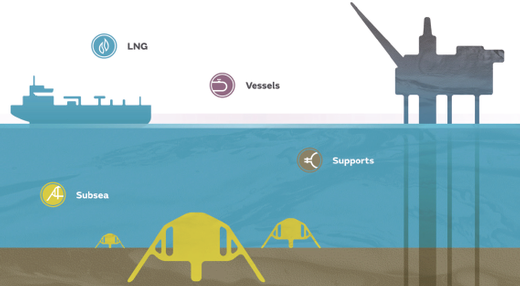

Torgy Group

Keeping it all together. Innovation, design and manufacturing of products for the world wide oil and gas industry. Solutions for extreme temperatures, endurance for the f...

COMPANY NEWS

TAMPNET AS

TOUGH net is now live

On Friday October 5th at 18:00 CEST Tampnet’s European Network Operations Centre (NOC) took over the operation of the TOUGH network on the Dutch Continental Shelf.

Previous presentation

Previous presentation